Cov khoom

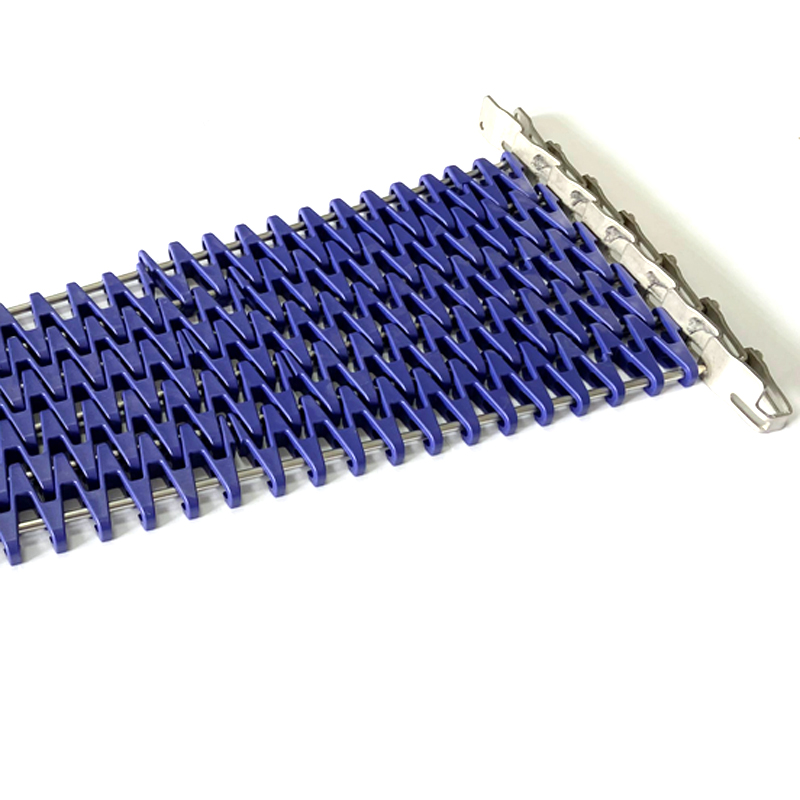

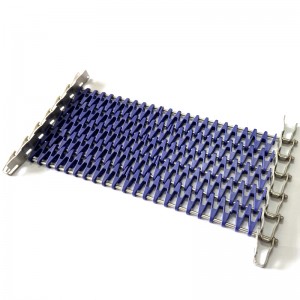

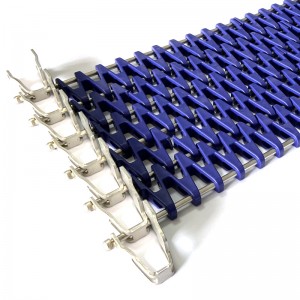

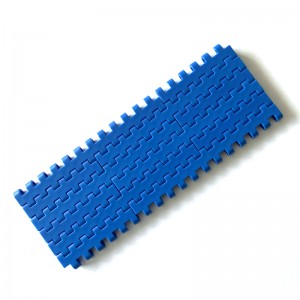

HASBELTS Conveyor U193 Spiralox Flush Grid

Sprocket Parameters

| Sprocket hom | Tus naj npawb ntawm cov hniav | Pitch txoj kab uas hla | Sab nraud txoj kab uas hla | A1 | Npog |

| H (mm) | C (mm) | mm | DF (hli) | ||

| 1-U193-17-40R | 17 | 207.4 ib | 215.8 ib | 98.0 ua | φ40 |

| 1-U193-17-50R | φ50 | ||||

| 1-U193-17-60R | φ60 |

Kev tu thiab tu ntawm kauv mesh siv conveyor

Kev tshuaj xyuas tsis tu ncua: Tsis tu ncua tshuaj xyuas tag nrho cov khoom ntawm cov kauv mesh siv conveyor, suav nrog cov kabmob, cov hlua, cov hlua mesh, thiab lwm yam, txhawm rau kuaj xyuas qhov hnav, xoob, lossis ua haujlwm tsis zoo.Tshwj xeeb tshaj yog rau mesh siv, impurities txuas rau lawv yuav tsum tau ntxuav tsis tu ncua kom tsis txhob cuam tshuam rau lawv cov kev ua haujlwm ib txwm muaj.

Lubrication: Tsis tu ncua lubricate cov bearings thiab chains ntawm kauv mesh siv conveyor kom txo tau kev sib txhuam thiab hnav.Rau cov kabmob, cov roj lubricating tuaj yeem ntxiv tsis tu ncua, thiab tag nrho cov kev txhaj tshuaj tuaj yeem xa mus rau 2/3 ntawm qhov chaw sab hauv ntawm lub thawv bearing;Soak cov bearings thiab shafts hauv lubricating roj txhua 4 lub sijhawm.

Ntxuav: Khaws cov kauv mesh siv conveyor kom huv si kom tsis txhob muaj impurities thiab av nkag.Thaum lub sij hawm conveying txheej txheem, cov khoom loj lossis cov khoom hlau hauv cov khoom yuav tsum raug zam kom tsis txhob nkag mus rau hauv lub conveyor kom tsis txhob muaj kev puas tsuaj rau cov khoom siv.

Tightening: Tsis tu ncua xyuas qhov nruj ntawm ntau yam ntawm cov kauv mesh siv conveyor, thiab ceev ceev kom raws sijhawm yog tias pom muaj qhov xoob.

Kev tu cov cuab yeej tsav tsheb: Kev saib xyuas tsis tu ncua ntawm cov cuab yeej tsav ntawm cov kauv mesh siv conveyor, suav nrog kev kuaj xyuas kev ua haujlwm ntawm lub tshuab tsav thiab reducer, nrog rau kev kuaj xyuas qhov nro thiab lubrication ntawm cov saw tsav.

Kev kaw haujlwm: Tom qab kaw lub sijhawm ntev, nws yog qhov yuav tsum tau khiav lub tshuab yam tsis muaj kev thauj khoom rau lub sijhawm kom ntseeg tau tias tag nrho cov khoom ua haujlwm zoo ua ntej ua haujlwm thauj khoom.Ua ntej nres lub tshuab, tag nrho cov ntaub ntawv nyob rau hauv lub conveyor yuav tsum tau xa mus kom tsis txhob muaj kev puas tsuaj los ntawm cov ntaub ntawv nyob rau hauv lub conveyor ntev.

Kev Tiv Thaiv Kev Tiv Thaiv: Tsim kom muaj kev tiv thaiv kev tiv thaiv tsis tu ncua, suav nrog kev tshuaj xyuas tsis tu ncua, lubrication, tu, thiab lwm yam, txhawm rau tiv thaiv cov khoom siv tsis ua haujlwm.Yog tias pom muaj lub suab txawv txav lossis kev vibration hauv cov khoom siv, nws yuav tsum tau nres tam sim rau kev tshuaj xyuas thiab kev daws teeb meem.

Los ntawm kev ua raws li kev saib xyuas cov kauj ruam saum toj no, kev pabcuam lub neej thiab kev ua haujlwm ntawm cov kauv mesh siv conveyor tuaj yeem txhim kho tau zoo, thiab qhov tshwm sim ntawm qhov tsis raug tuaj yeem raug txo.

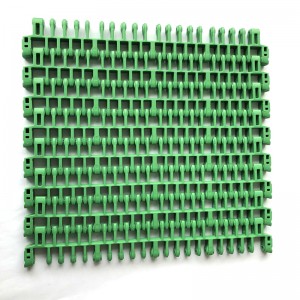

Cov txheej txheem ntawm customizing modular yas mesh siv

Tsim thiab tsim cov phiaj xwm ntau lawm raws li cov neeg siv khoom xav tau thiab cov khoom siv tshwj xeeb.

Ua cov pwm, xaiv cov ntaub ntawv yas uas tsim nyog, thiab txhaj cov yas yas los ntawm kev sib xyaw cov tshuab txhaj tshuaj molding.

Splice raws li tus neeg siv khoom qhov dav thiab ntev los ua ib qho khoom siv yas mesh siv.

PRODUCT CATEGORIES

Tsom ntsoov rau kev muab cov kev daws teeb meem mong pu rau 5 xyoos.